PULTRUDED FIBERGLASS GRATING

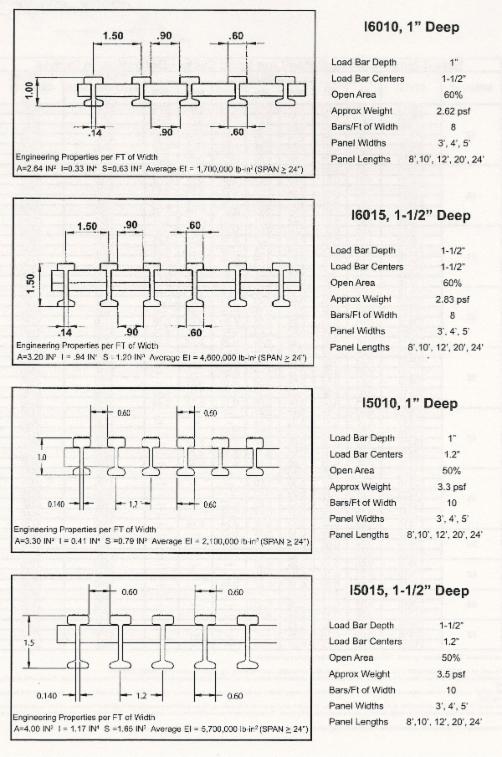

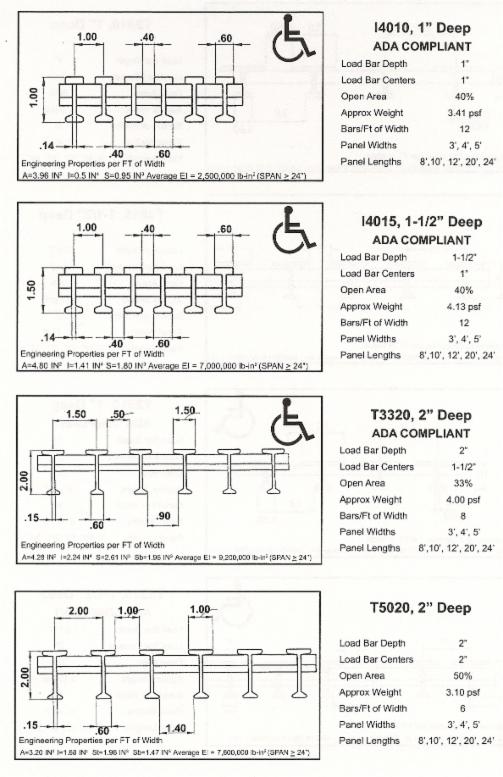

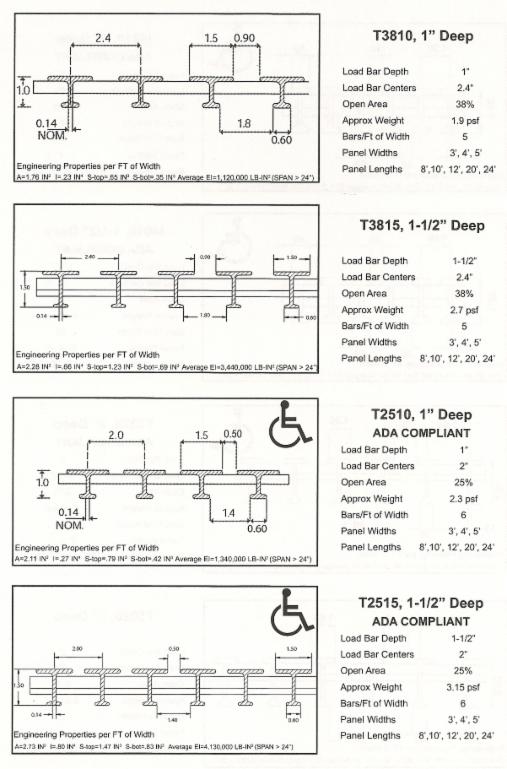

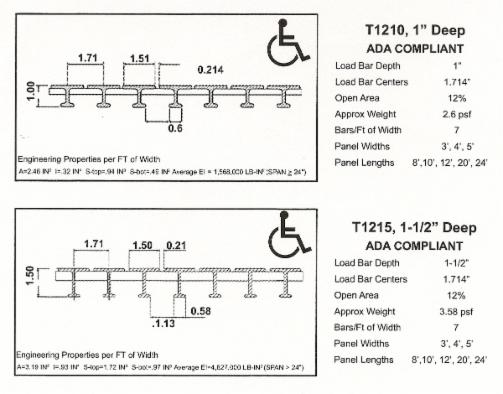

Pultruded Fiberglass Grating is constructed from individual components that are assembled to create a grating panel. The primary component is called the "load bar" and is available in either an "I" bar profile or a "T" bar profile. Typically the "I" bar grating is used for industrial applications because of its high strength characteristics. The "T" bar profile is more commonly used for pedestrian walkways because of its wider surface profile. The second component of pultruded grating is the "tie bar". The "tie bars" hold the load bars in position and are typically spaced at 6" or 12" intervals.

Pultruded grating contains a higher ratio of fiberglass than molded grating making it ideal for applications requiring higher loads across longer spans. Pultruded grating is a unidirectional material which means the load bars must be place in the span direction for proper installation. Since Pultruded Grating is an assembled product, it can be offered in a wider variety of panel sizes.

RESIN SYSTEMS Pultruded grating is available in two resin formulations both are fire retardant with an ASTM-E-84 flame spread rating of 25 or less. Standard colors are Safety Yellow or Dark Gray.

ISOFR is a polyester resin system used for general applications

VEFR is a vinyl ester resin system used for corrosive applications

Sample of I6015-6 Pultruded grating in Safety Yellow

AVAILABLE PULTRUDED GRATING

Sample of T2510-12 Pultruded grating in standard dark gray with quartz grit.

Sample of T2510-12 Pultruded grating in standard dark gray with quartz grit.

I6015-6 Pultruded grating in dark gray